Basic Facts About Air Compressor Tools

Air tool is a pneumatic tool. It is either a pneumatic powered device or air powered tool. The air devices are typically driven by compressed air provided from any type of gas compressors. Such pneumatic tools can likewise be driven by co2 (CO2) compressed and kept in small cylinders for simple mobility. It is rather safe to run pneumatic tools and upkeep of such tools is likewise much easier compared with electric power tools.

Even more, pneumatic tools have high power-to-weight ratio and hence, a lighter and smaller sized device will be able to accomplish the job that huge electrical power tools perform.

The pneumatic tools of general grade are rather affordable however they have shorter life. For this reason, they are termed in tooling industries as disposable devices. However, the pneumatic tools of commercial grade are a lot more expensive however have long life periods.

Typically, all pneumatic tools are less expensive when compared to their comparable electrical power tools. These devices were somewhat out of favor in the do-it-yourself (Do It Yourself) markets previously but due to the convenience of operation and safety, many Do It Yourself people have started using them. Anyways, production and commercial settings have actually been making use of pneumatic devices as obligatory devices for long.

Air compressor equipment have particular specific technical terms when it comes to option of the best device. Atmospheric pressure measured in psi/bar, totally free speed in rpm, horse power in hp, air intake in cfm/scfm or m3/min, and spindle size, and so on identify the choice of the pneumatic tools. It is mandatory for all pneumatic devices to have ISO 9001:2008 certifications.

A lot of nations demand this ISO 9001:2008 certification for import or export of pneumatic tools, along with CE marking on them.

Air Compressor

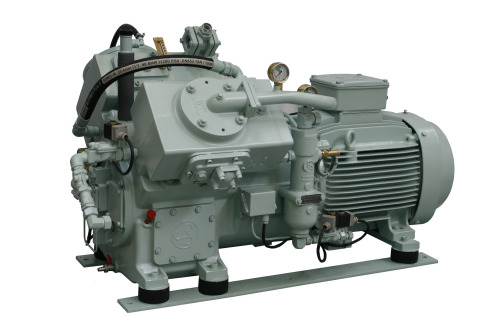

Air compressors are gadgets that transform power into kinetic energy. The power source is typically an electric motor, a gasoline engine or a diesel engine. The air compressors compress and pressurise the air, which is released in quick and brief bursts on command. Several kinds of air compression techniques are available but the significant classifications are favorable displacement compression and negative displacement compression. Air compressors are divided into other small categories and models based on the following elements.

Kinds of Air Compressor

By Design and Operational Principle

1. Reciprocating Compressor

2. Turbo Compressor

3. Rotary Screw Compressor

Based on Variety of Stages

1. Single Phase Compressor

2. 2 Stage Compressor

3. Multi Phase Compressor

Based upon Pressure Limitations

1. Low Pressure Compressor

2. Medium Pressure Compressor

3. High Pressure Compressor

4. Super High Pressure Compressor

Based on Capacity

1. Low Capacity Compressor

2. Medium Ability Compressor

3. High Ability Compressor

Based on Cooling Technique

1. Water Cooled Compressor

2. Air Cooled Compressor

Positive Displacement Air Compressors

Positive Displacement air compressors work when air is forced into a chamber and the volume of the chamber is decreased to accomplish air compression. Many of the piston kind of air compressors utilizes this concept of pumping air into air chamber by the continuous movement of pistons. These compressors make use of on-way values for assisting the air into the chamber and the air gets compressed. Another kind of positive displacement compression technique is used in rotary screw compressors. 2 helical matching screws guide air into the chamber when they turn and the volume of the chamber gets decreased when the screws turn. Likewise, vane compressors use slotted rotors with different blade placements for assisting air into the chambers and compress their volumes.

Negative Displacement Air Compressors

Unfavorable displacement air compressor is mainly centrifugal compressor. This compressor utilizes a spinning impeller, which speeds up to produce centrifugal force and then decelerates recorded air, pressurising the air.